We develop/modify/utilize a wide range of high-pressure technologies including the LLNL diamond anvil cell (DAC; Livermore modification of the Mao–Bell DAC), membrane DAC, modulating DAC, Mossanite anvil cell, and large-volume Edinburgh cells.

Membrane DAC

Modulating DAC

Large Volume Press

Membrane DAC

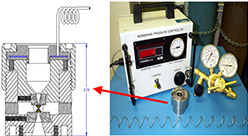

It is essential that our group have an instrument to remotely adjust sample pressure inside the DAC while it is being bombarded with x-rays inside a closed synchrotron hutch. A system was developed to precisely and systematically adjust sample pressure between the diamonds of the DAC unit from a remote location. This was accomplished with the addition of a small pressure membrane assembly mounted to the DAC that replaced the manual pressure adjusting screws. The membrane works by injecting a metered amount of inert gas inside the flexible membrane causing it to expand. As the membrane expands it applies force to the DAC's piston increasing sample pressure between the diamonds. To operate the membrane, a pressure controller was assembled that utilized a standard gas cylinder at 2,200 psi as the pressure source. Since the bulk of our experiments are performed off-site, the controller was designed to be small, lightweight, and portable.

The controller consists of a small steel box housing a metering valve for fine pressure control, a digital readout for very precise membrane pressure monitoring, a vent valve to lower the membrane pressure and small-orifice tubing that supplies gas to the membrane. With the introduction of the new membrane DAC, it is now possible to perform experiments without having to disrupt the synchrotron beam for mechanical DAC pressure adjustments and realignments. This new instrument has greatly improved the quality and quantity of data collected.

Modulating DAC

High pressure research performed with diamond anvil cells has traditionally been limited to studies of materials under static conditions. While this permits the study of phase transitions and hysteresis, it can not address dynamic phenomena such as transformation rates, mechanisms and other kinetically driven processes. This is important not only to develop an understanding of kinetic processes, but also bridging the timescales and regimes covered by dynamic high pressure techniques such as explosively driven shock waves and gas guns.

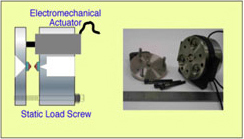

The High Pressure Physics group is developing a modified diamond anvil cell to address dynamic issues. While this cell will not address the pressure–temperature–strain rate regime of shock waves, it will complement this well-established field of research by addressing dynamic phenomena such as melt/re-crystallization and more generally the kinetics of phase transformations. To this end, we are developing a DAC that incorporates piezo-electric actuators that allow us to modulate the pressure around a fixed point. Thus we have a method for modulating the pressure in a DAC.

With the modulated DAC, we will investigate the material under pressure using a time-resolved probe. The frequency of modulation is limited by the mechanical response time of the cell. Currently we have driven our cell at modulation time scales of several hertz, but with improved design we hope to advance to several kilohertz. Thus, the time scale of the probe must be at the level of milliseconds or better. We are currently using a Q-switched YAG for optical studies, and plans are underway to exploit the time-resolved character of synchrotron x-ray sources to make time-resolved x-ray structural studies.

Large Volume Press

Many macroscopic diagnostic techniques require sample sizes beyond those provided by DACs. For this purpose we have installed a Paris–Edinburgh Cell (PEC), a large volume press capable of 250 tons of load and sample sizes of many mm3. Compared to other large volume presses capable of similar loads this one weighs only about 100 pounds and fits easily on a lab table.

The picture shows our PEC inside a transparent enclosure connected to a fume hood for purging with an inert atmosphere. It has been equipped with a liquid nitrogen reservoir to allow cooling of the sample/anvil region to a temperature of 80 K in about 20 minutes. We are using both toroidal and Bridgman type anvils. At present we are employing the PEC primarily to perform research on condensed molecular gases, e.g. CO, with the goal to manufacture new materials under extreme conditions of pressure and temperature and to recover those to the ambient environment. The nature of the recovered samples is then investigated by macroscopic diagnostic techniques, e.g. nuclear magnetic resonance and calorimetry, as well as optical spectroscopy or x-ray technologies. Of specific interest is the possibility that the recovered material stored some or all of the energy required to compress the sample which would make it a candidate as a high-energy-density material.